Key Takeaways

- Chris Doel, a UK-based maker, repurposed disposable vape batteries into a functional DIY power system, demonstrating practical electronics skills and creative resourcefulness.

- The project emphasizes modular assembly, safety precautions, and battery management strategies to safely reuse lithium-ion cells from used devices.

- The build went viral on YouTube, highlighting public interest in maker culture, sustainable electronics projects, and innovative personal energy solutions.

- Doel’s approach blends entertainment and education, inspiring hobbyists to explore small-scale renewable and repurposed energy setups.

Inside Chris Doel’s Wild, Ingenious, and Surprisingly Important Battery-Reuse Experiment

In the world of internet DIY makers, few creators combine eccentric humor, rigorous engineering, and an oddly noble mission quite like Chris Doel, the British YouTuber who has made a name for himself doing the impossible with disposable vape batteries. His latest project—an improvised home-scale Powerwall built almost entirely out of the lithium cells found inside single-use vapes—has become one of his most ambitious and absorbing builds to date.

What began as a casual idea—“Could I power my entire workshop off these things?”—quickly evolved into a multi-month engineering marathon, involving hundreds of vape devices, custom testing rigs, 3D-printed modules, meticulous battery balancing, and a level of commitment that borders on the absurd. But behind the jokes and fast cuts is a serious investigation into the hidden potential of the tiny rechargeable cells that millions of people throw away every week.

This is the story of how he did it.

COLLECTING HUNDREDS OF VAPES — A SCAVENGING MISSION

To assemble a battery system large enough to run a workshop, Chris calculated he would need either:

- 1,400 small vape cells, or

- Around 500 larger disposable vapes, the kind commonly found in festivals, high streets, and gutters.

He spent weeks collecting thrown-away devices from public spaces, bins, and designated vape-recycling containers. Festivals proved especially fruitful. Vape shops contributed boxes of customer-disposable units. By the end, Chris and his friend Max had amassed a chaotic mountain of disposables—all destined for disassembly.

But the real challenge had only begun.

HALF THE BATTERIES WERE DEAD — SO HE BUILT A “SMOKING MACHINE”

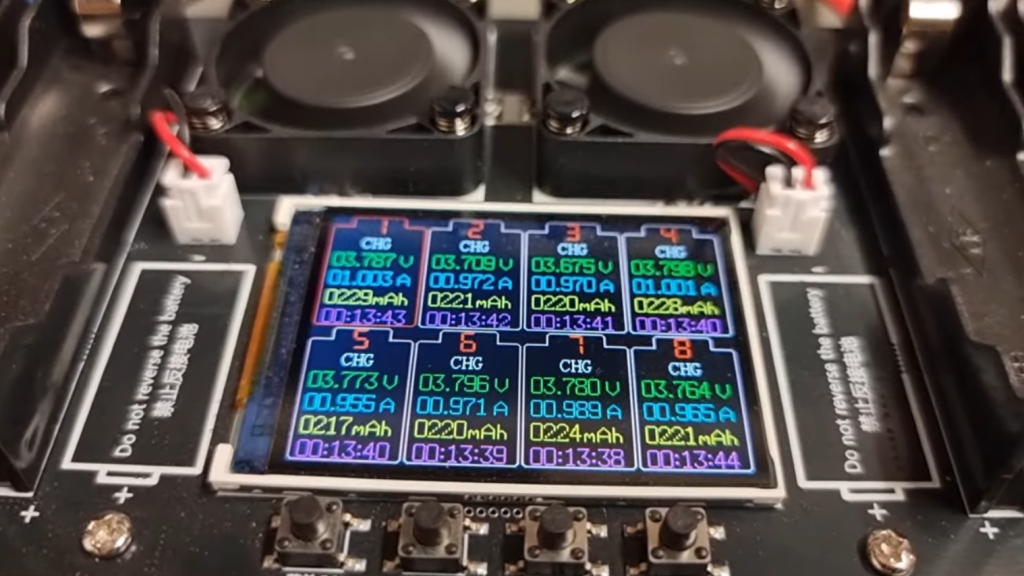

Single-use vapes are notorious for over-discharging their internal lithium batteries. A cell that drops too low becomes unstable and unsafe to reuse. Chris discovered that nearly 50% of his collected units were already too far gone.

Testing them manually—one by one—would have meant days of tedious work. Instead, he improvised a solution that could only come from a maker with equal parts engineering skill and comedic flair:

A CPAP-powered automated “vape-testing machine.”

He connected the respirator to a tube system that “puffed” air through a vape.

- If the vape lit up and activated, the battery was still above 3V.

- If it didn’t, it went straight to the reject pile.

The contraption looked absurd. But it worked brilliantly, sorting hundreds of devices in a fraction of the time.

DISASSEMBLING AND HARVESTING THE CELLS

Once sorted, Chris began the painstaking process of extracting each cell:

- Opening the disposable chassis without damaging the battery.

- Removing residual e-liquid or electronics.

- Cataloging the voltage of every reusable cell.

- Grouping them by capacity and health.

The cells he salvaged were surprisingly high quality. Many came from reputable manufacturers; a significant number had barely been used. Chris remarked repeatedly that it made no sense for such well-made rechargeable cells to be manufactured for single-use products.

By the time he had finished harvesting, he had enough good cells to start building something serious.

BUILDING THE MODULES — 3D PRINTING, FUSE WIRE, AND TESLA-INSPIRED LAYOUTS

The design philosophy for the Powerwall was inspired by the modular structure of Tesla’s Model X battery packs:

Step 1:

Create cell “blocks.”

Chris designed custom 3D-printed frames that held nine cells each in secure parallel groups.

Step 2:

Add safety fuses.

Every single cell received a small, hand-soldered fuse wire—an exhausting task repeated hundreds of times. This ensured that if one cell failed, it wouldn’t compromise the entire system.

Step 3:

Connect each block with heavy copper busbars.

The copper strips were cut, drilled, and soldered to form the backbone of the electrical structure.

Step 4:

Assemble the full battery bank.

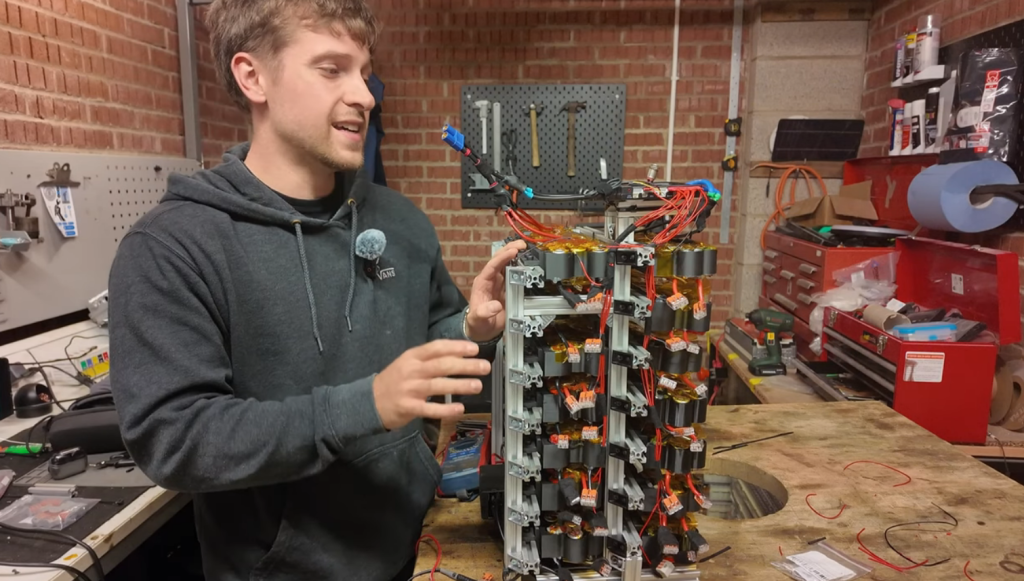

He built:

- 14 series groups (14S) to reach a working voltage around 50V

- 46–60 cells per group, depending on capacity

- Final energy storage: roughly 2.5 kWh

Everything was tested with precision tools—multimeters, load testers, thermal probes, and battery management software—giving the final structure the appearance of a lab-grade engineering prototype rather than a “junk battery” experiment.

TWO MONTHS OF WORK: “THE MONTAGE DOESN’T DO IT JUSTICE”

Even with 3D printing, power tools, and years of maker experience, the sheer repetition was brutal.

Chris joked that the final montage “barely shows 5% of the real pain.” The project consumed:

- Weeks of soldering

- Entire spools of copper

- Dozens of 3D-printed parts

- Several failed prototypes

- And a workshop floor permanently covered in torn vape shells

But slowly, piece by piece, the Powerwall became a functioning energy system.

INSTALLING THE BATTERY — AND POWERING THE WORKSHOP

Chris wired the final battery into a charge controller and inverter setup capable of powering lights, tools, and electronics around the workshop. The system ran smoothly, delivering stable voltage and drawing from cells that hours earlier had been waste littering public streets.

When he switched the system on for the first time, the moment was understated—no dramatic music, just quiet satisfaction. For a build made from devices meant to be thrown away after a few hundred puffs, it was a remarkable transformation.

WHAT HIS PROJECT REALLY SHOWS

Chris never positions himself as an activist. He’s a builder, a tinkerer, a guy who enjoys making ridiculous ideas real. Yet his project unintentionally highlights several truths:

- The lithium cells inside disposable vapes are robust, high-quality, and fully rechargeable.

- Millions of them are disposed every week.

- With enough patience and technical care, they can be integrated into large-scale energy systems.

- The gap between “waste” and “valuable component” is often just a matter of perspective and design.

The beauty of Chris’s Powerwall isn’t just in the finished hardware—it’s in revealing a hidden layer of potential inside everyday products.

A MAKER, A CAMERA, AND A MOUNTAIN OF BATTERIES

In typical fashion, Chris closes his video with self-deprecating humor, insisting he’ll probably never do something this massive again. But viewers know better. Whether he’s building a battery from AA cells, running bizarre experiments, or reverse-engineering consumer tech, Chris Doel operates with the same blend of curiosity and stubbornness that defines great maker culture.

His disposable-vape Powerwall is more than a viral stunt. It’s a showcase of what’s possible when engineering skill meets imagination—and when someone bothers to look twice at the things the rest of us throw away.

Proof once again that geeks are the best at turning the ordinary into the extraordinary.